Chemicals for the chemical industry

Product Lineup

SS-3 (Brush-on type)

This pickling agent was developed for the pickling of austenitic stainless steel using brush-on (brush painting) application. This gel-type pickling agent has a good spreadability like paint, and this consistency makes it ideal for brush-on applications. A soaking bath is not necessary, making it an effective choice for stainless structures that cannot be immersed in pickling agent, including large objects, heavy objects, and fixed objects which are difficult to move such as anchors. Since only brushed-on areas are pickled, this product can be used for partial, localized pickling applications. This agent has a nitric acid base compounded with hydrofluoric acid and other reagents.

SS-3 (Spray type)

This pickling agent is for spraying application. This type is effective where brush-on application is difficult (situations where there are dangerous work conditions in high places, or parts with complex shapes which are difficult to handle with brush application) or where pickling must be performed over a wide area. Spray work can also be performed quickly. This agent has a nitric acid base compounded with hydrofluoric acid and other reagents.

FSUS-5

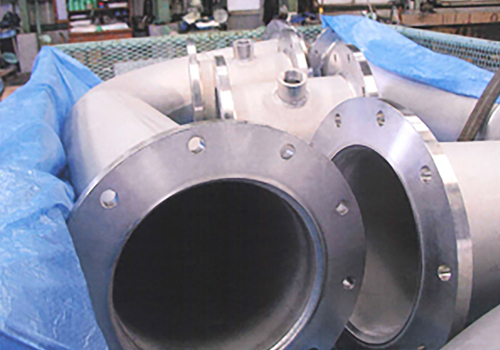

This pickling agent is for immersion application. By simply soaking objects in an immersion bath, they can be finished with an even coating, making this type of pickling ideal for small objects or objects with complex shapes. It can also be flushed through pipes with an acid-resistant pump used to circulate the pickling agent. The bath can be diluted with water and its temperature adjusted to easily control the finish quality and processing time. This agent has a nitric acid base compounded with hydrofluoric acid and other reagents.

FC-1

This pickling agent is for washing to remove the black coating (mill scale) that occurs on steel material surfaces as well as general rust and scale (metal precipitate) that occurs on plumbing and heat exchangers. It can remove scale from metals such as calcium and magnesium as well as silica-based scale. It also includes an iron corrosion inhibitor so that the pickling process does not damage the base metal. This agent has a hydrochloric acid base compounded with hydrofluoric acid and other reagents, and is prepared as 3 types, with consistency adjusted depending on the method of application: brush application, spray application, or immersion soaking.

NN-100

This passivating pickling agent is for pickled stainless steel that has been machined or buff polished. This agent has a nitric acid base and is prepared as 2 types, with consistency adjusted depending on the method of application: brush application or spray application.

IM-100

This pickling agent is for washing to remove the black coating (mill scale) that occurs on steel material surfaces as well as general rust. It includes an iron corrosion inhibitor so that the pickling process does not damage the base metal. This agent has a hydrochloric acid base and is prepared as 2 types, with consistency adjusted depending on the method of application: brush application or spray application.

FF-10

This is a friction reducing agent used in the manufacture of drawn steel pipe. It includes a metal corrosion inhibitor so that the process does not damage the base metal. This agent is compounded with organic acids and amines.

Trilon B

This is a strong oil-removing detergent ideal for removing oils adhered to metal surfaces prior to pickling. It is a strong alkaline type detergent with sodium metasilicate as the primary component. It can be used for the removal of various oil contaminants by adjusting the solution's concentration and temperature. In its flaked state it can be slightly difficult to dissolve in water, but it is effective for cleaning when mixed with water and scrubbed onto surfaces like a cleanser. It can also be completely dissolved in water and used for immersion soaking.

Neutralizing Agent

This chemical neutralizes leftover pickling agent solutions and waste liquid. This liquid slurry has a calcium hydroxide base which, when mixed at the appropriate amount with leftover pickling solution and waste liquid, makes the liquid neutral to weakly alkaline. Along with the neutralizing process, fluorine in the liquid reacts with insoluble calcium salts and precipitates, which contributes to lowered fluorine content, an important factor for environmental standards for waste water.

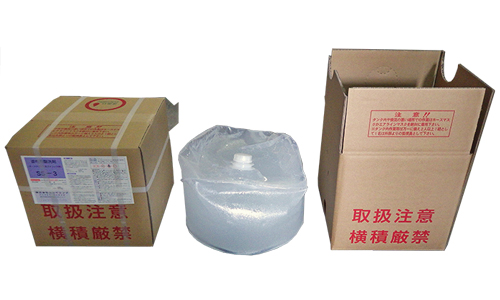

Packaging

Each product is packaged as shown using the following parameters. -: Not available

| 20 kg package Bag-in-box |

10 kg package Bag-in-box |

3 kg package Polyethylene container |

2 kg package Polyethylene container |

10 kg package Polyethylene bag × 4 bags |

|

|---|---|---|---|---|---|

| SS-3 (Brush-on type) |

|

|

|

|

− |

| SS-3 (Spray type) |

|

- | - | - | - |

| FSUS-5 |  |

- | - | - | - |

| FC-1 |  |

- | - | - | - |

| NN-100 | ◯ | - | - | - | - |

| IM-100 |  |

- | - | - | - |

| FF-10 |  |

- | - | - | - |

| Trilon B | - | - | - | - |  |

| Neutralizing Agent |  |

|

|

|

- |

Bag-in-box (20 kg, 10 kg)

Specifications: (Inner packaging) filled and sealed in polyethylene (acid resistant, alkali resistant) container

(Outer packaging) Cardboard box

Polyethylene container (3 kg, 2 kg)

Specifications: (Container) filled and sealed in polyethylene (acid resistant, alkali resistant) wide-mouth bottle (with inner lid)

(Outer packaging) Polyethylene bag

Polyethylene bags (10 kg × 4 bags)

Specifications: (Container) Packaged in 10 kg portions in polyethylene bags (heavy duty) × 4 bags

(Outer packaging) Cardboard box

Information Related to Manufactured Pickling Agents and Other Chemical Products

In order to convey information on the human and environmental hazards of our company's manufactured products, SDS (Safety Data Sheets) compliant with GHS (Globally Harmonized System of Classification and Labelling of Chemicals) are prepared and made available for each product. Our product's labels are also prepared and used in a GHS-SDS-compliant manner.

Please contact us if you require any of our products' Safety Data Sheets.